By default, the integrated ERP module tacoss.eSCALE is used to record weight-based processes on a truck scale and to assign them to the order management of tacoss.eTRADE for purposes of accounting.

In addition to the corresponding program window, which is available to users within tacoss.eTRADE, weighing orders can also be processed directly by the driver of the vehicle using a self-weighing terminal on an unmanned scale.

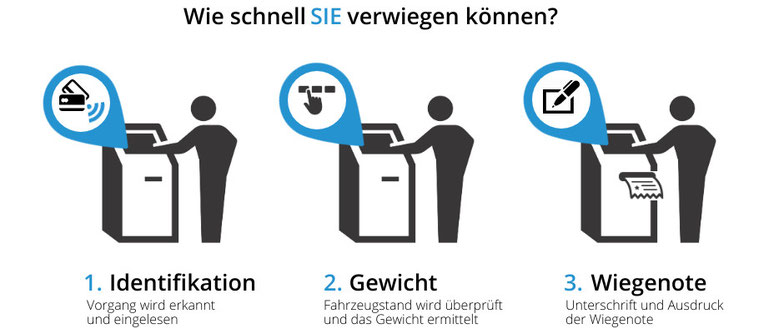

The concept

Mit der Einbindung RFID-basierter Datenströme in die Abwicklung von Warenvorgängen wurde der Grundstein für die Abwicklung von Warenanlieferungen über Selbstverwiegungs-Terminals gelegt. Zu jedem Zeitpunkt in der Prozesskette einer Warenanlieferung - von der Zufahrtskontrolle zum Firmengelände über die Wägung, Anlieferung und Ausfahrt - stehen die erforderlichen Daten mittels RFID Übertragung zur Verfügung.

Only a few entries at the self-weighing terminal are required so that the driver can deliver his goods quickly. The direct communication with tacoss.eTRADE ensures that all information in regard to the delivery can be checked and processed accordingly in the ERP system. This includes, for example, information on the contract and the transaction, document information that is required with the corresponding signatures, which can be entered directly at the terminal via an automatic request.

Efficiency and speed

Perhaps the biggest advantage is the extra speed at which drivers can deliver their goods. Especially at peak times, e.g. during harvesting, it can be very helpful. The length of the queues and the associated waiting times are reduced, which satisfies your carriers and minimises stress for your employees at the same time.

DRIVERS LIKE IT

It is important for the drivers to be able to deliver the goods quickly and easily. Language selection at the terminal also makes it easier for drivers from other European countries who speak a different language.

ALWAYS ENOUGH STAFF

The capacity of a self-service terminal is not limited by the number of free scale employees, but only by the number of systems installed. This results in a better deployment of personnel. A single employee can monitor multiple terminals and support drivers as needed.

LESS MISTAKES

The higher the degree of automation, the fewer errors can be made. Incorrect entries in the system and non-adherence to process steps are less likely to occur in an automatic procedure.